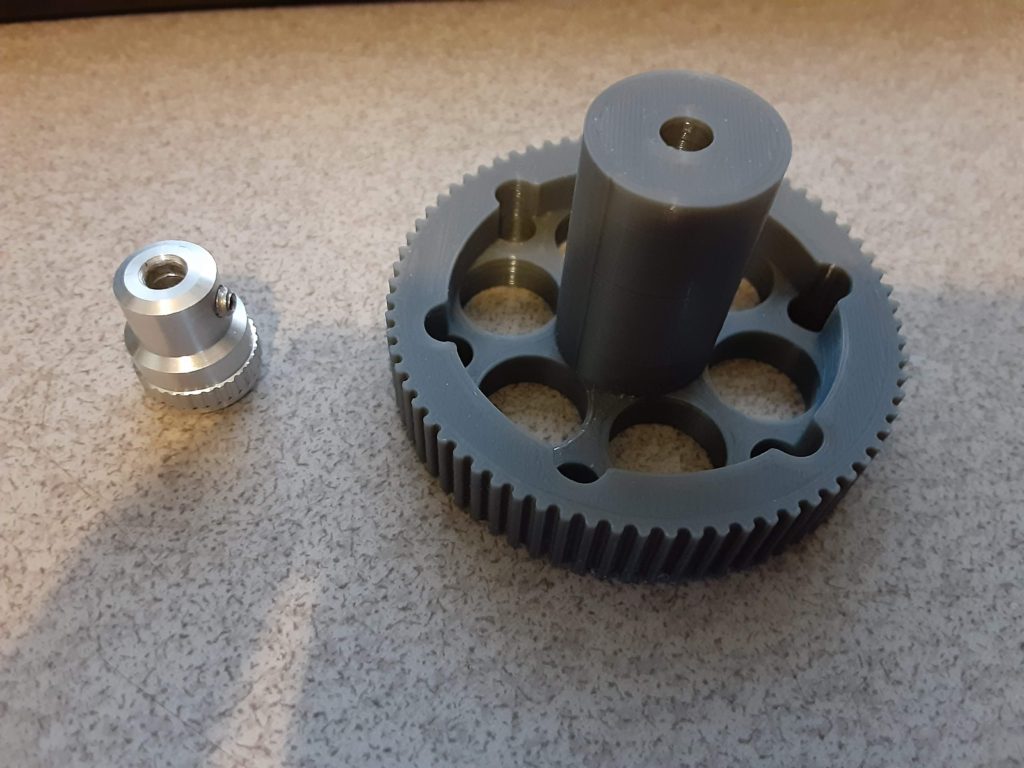

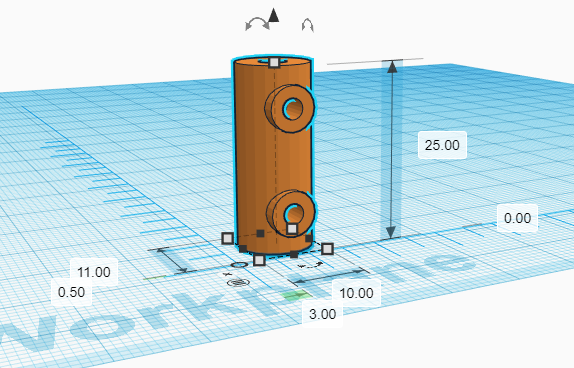

Not wanting to drive back down to Ace, I started rummaging through my junk pile to see if there was anything I could use to fabricate a new coupler to replace the aluminum spacer I had tried to use. I looked at some 1/2″ steel bar stock I have, but decided I really need a lathe to make that work like I want, so I continued to rummage. I happened to run across a block of HDPE that I had made by melting down plastic milk cartons, and decided maybe I could cut and drill a chunk of that and make it work. As I secured it in the vise and started looking for a saw, it occurred to me that if I was going to make one out of plastic, why not 3D print it? So off to the computer, and I spent about 5 minutes in TinkerCAD to come up with this:

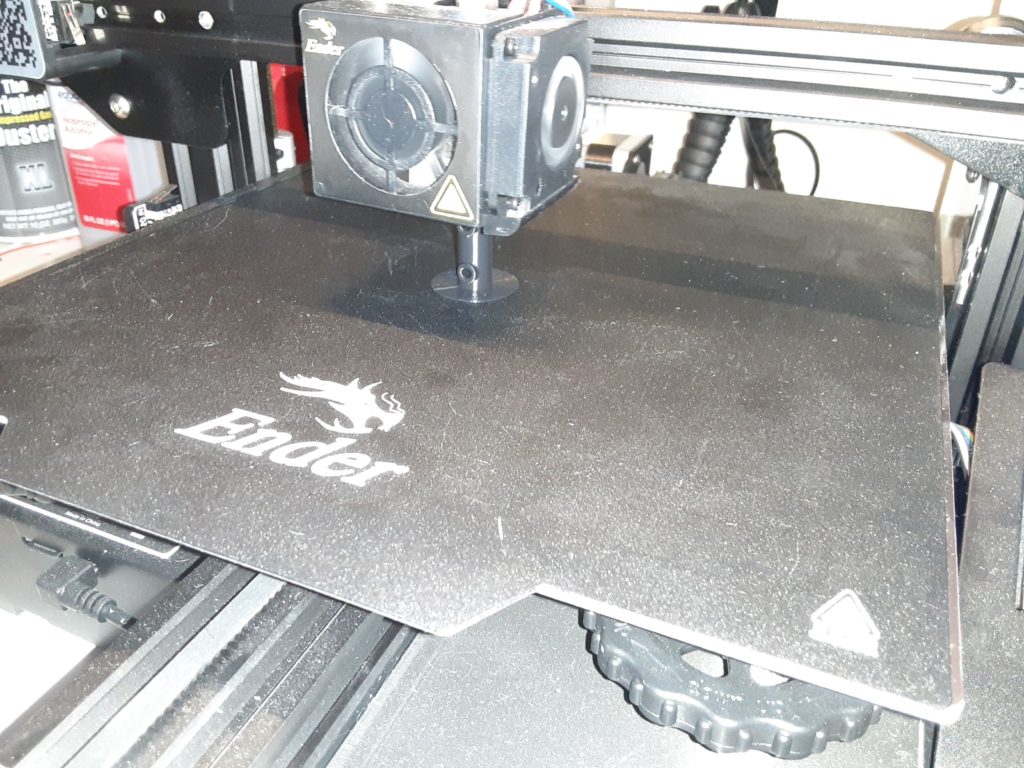

I sliced it in Cura and set it for 100% infill to be sure I’d have enough thickness to cut threads into. At $20/kg, Cura tells me this piece is going to cost the princely sum of 5 cents, even with all that infill. I also kicked the print temperature up to 210C, as that will supposedly result in a stronger print. Sent it over to the printer, and 30 minutes later, I have a part:

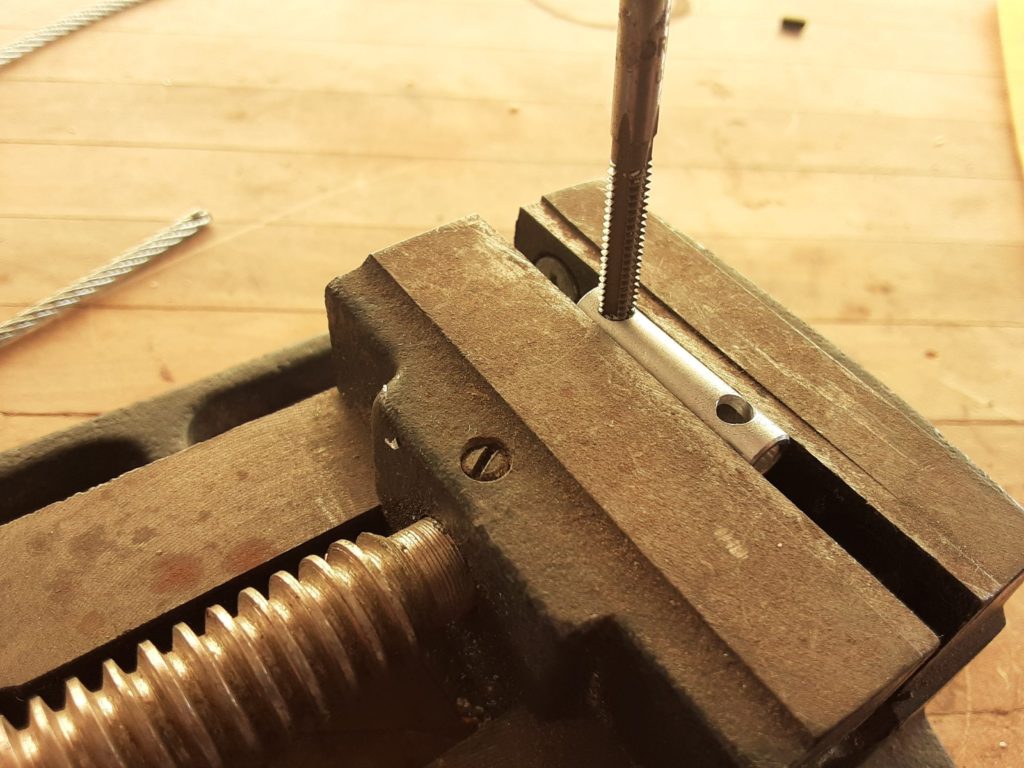

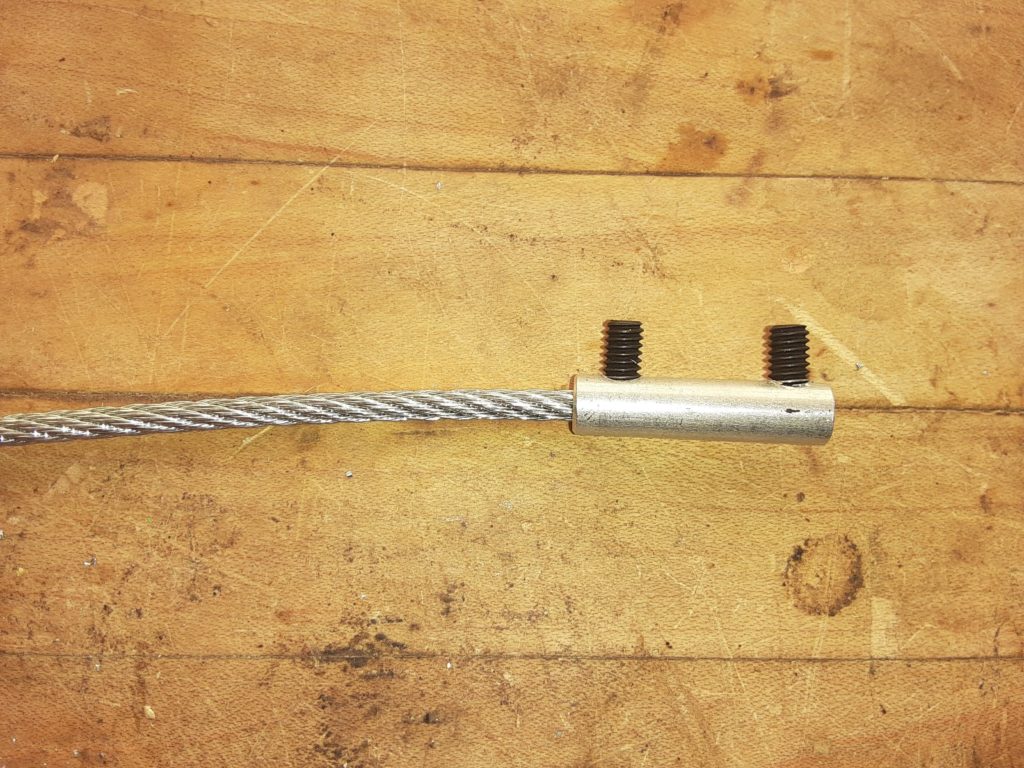

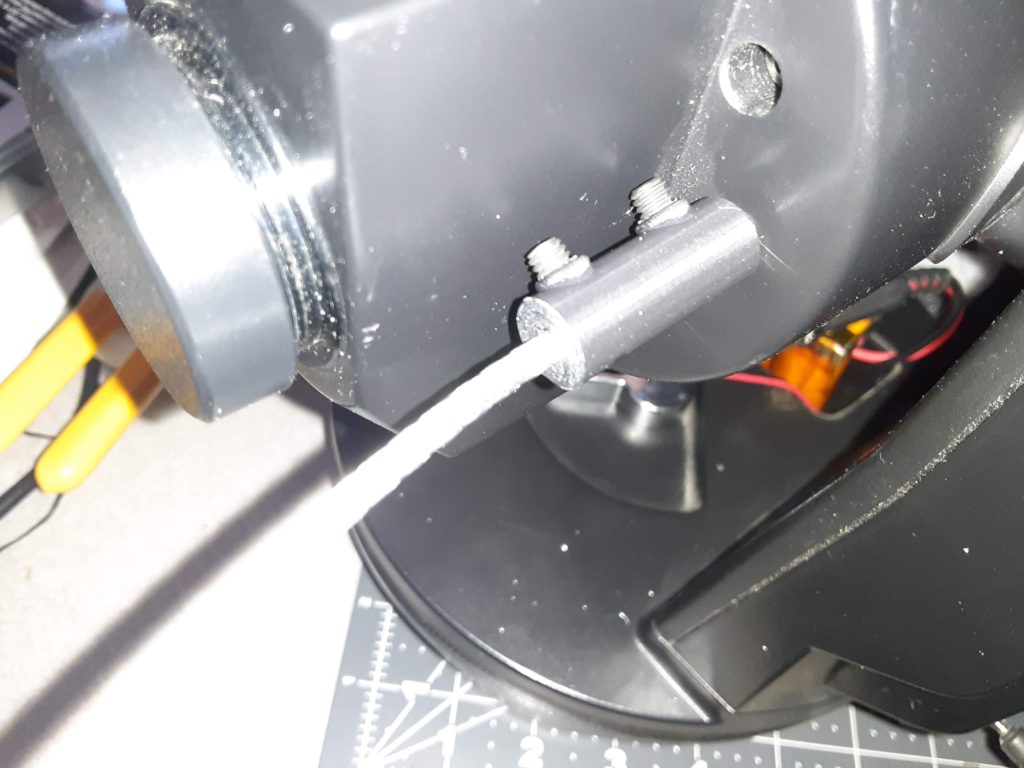

When I designed it in TinkerCAD, I used 3mm holes for the setscrews, thinking I would drill them out, then use the tap, but I ended up tapping them both without bothering to drill it, and it worked great. I carefully threaded the setscrews in, and cinched them down on the cable and focus rod:

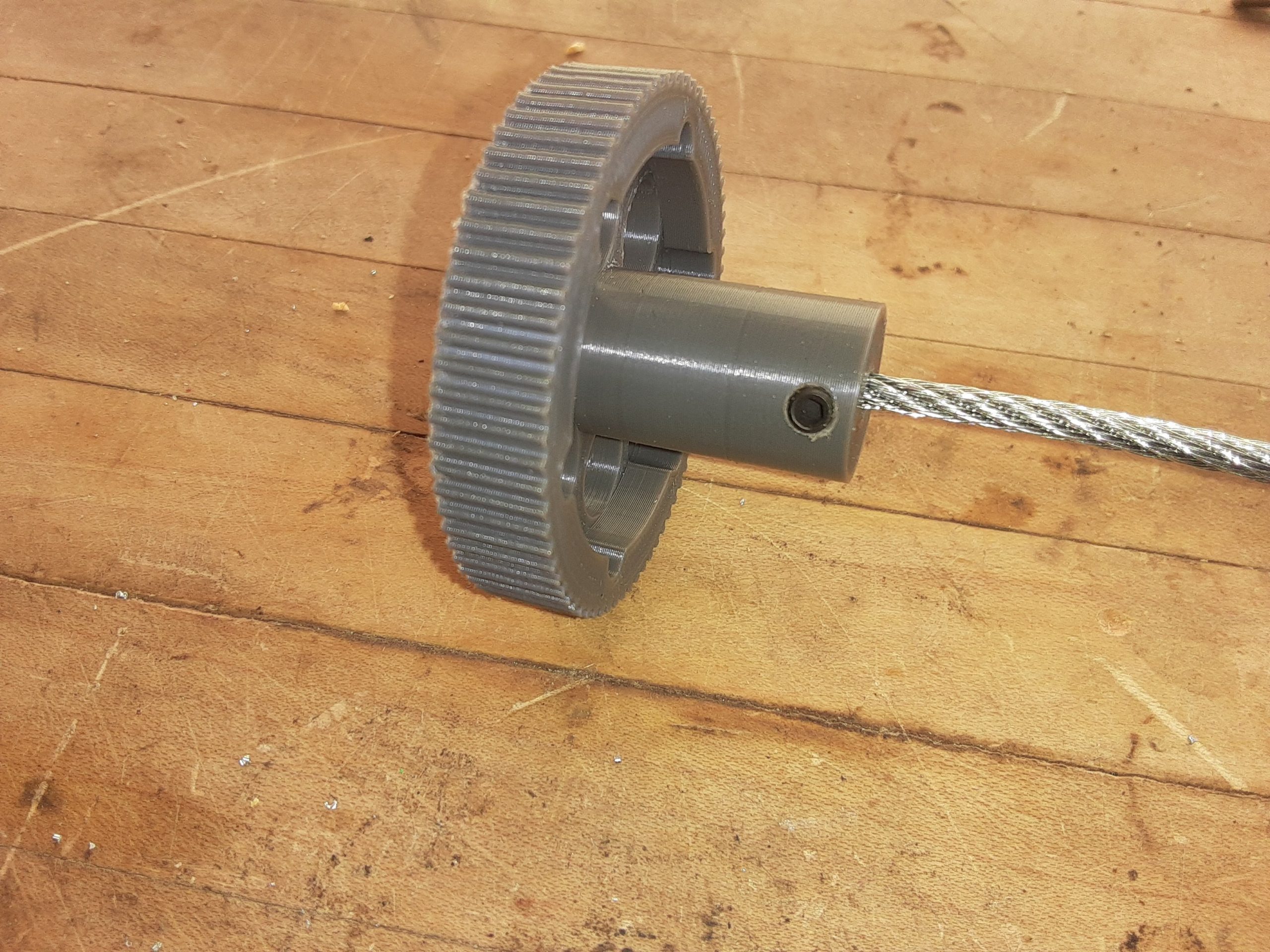

Gave the knob a few test spins, and the objective lens is now focusing smoothing in and out. Here is the finished extender: